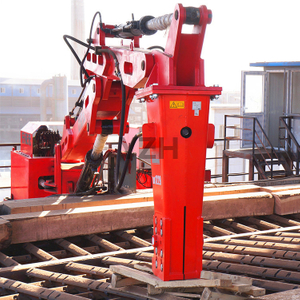

Rock Breaker Boom System

YZH rock breaker boom system is a complete product matrix covering the 1-ton to 18-ton class, with 40 models precisely adapted to heavy-duty applications with radii ranging from 1 meter to 17 meters. Users can choose from a wide range of rock breaker boom system, control and power packages to match hammering performance to job requirements. Among YZH's extensive B-series product line, the BC series is the "special forces", and the BC550 rock breaker boom system is the best of them. With a bare weight of 6720KG, this breaker booms far exceeds similar models, demonstrating its powerful working strength. In order to support such a large body, the engineers designed a reinforced round base for BC550 rock breaker boom system, which is made of high-strength alloy material and innovative structural design, increasing the load-bearing capacity by 30% compared with the conventional base, ensuring that the equipment remains stable during high-intensity crushing operations, and building up a solid foundation of safety for high-efficiency operations.

Features of BC550 rock breaker boom system

1.BC550 rock breaker boom system has a strong structure, the cross-section area of the boom is 300x300x18MM, the torsional strength is 25% higher than similar products, the bending resistance is 30% stronger, the operation is stable and durable.

2. The circular base adopts ring structure and high strength alloy, the load bearing capacity is 40% higher than the square base, and rock breaker boom system can be stably supported under heavy load conditions.

3. Flexible and diversified control, supporting manual precise operation, remote wireless remote control and automated intelligent control to meet different operational needs.

4.Wide range of application scenarios, suitable for ground mining, construction and demolition, as well as underground ore crushing, roadway repair and other heavy-duty crushing operations.

Advantages of BC550 rock breaker boom system

At the level of capacity enhancement, the BC55 rock breaker boom system is equipped with an advanced industrial-grade servo drive system, which gives it amazing accuracy and speed. Its repetitive positioning accuracy reaches ±0.02mm, which is equivalent to one-third of the diameter of a hairline, and with a running speed of up to 1.5m/s, the efficiency of single-station operation is more than 300% higher than that of traditional manual labor. Not only that, the BC550 rock breaker boom system has the characteristic of 7×24 hours uninterrupted and stable operation, which ensures that the rock breaker boom system will not stop working if the mining line does not stop. Equipped with industrial-grade hydraulic drive system and remote control system, it can accurately locate the target ore, and the impact force of single crushing is up to 500 tons, which improves the efficiency by 200% compared with the traditional blasting mining. In the face of granite and other hard ores with a hardness of 7 on the Mohs scale, the rock breaker boom system can handle up to 800 cubic meters per hour, far exceeding manual mining and ordinary crushing equipment.

In terms of reducing labor intensity, YZH BC550 rock breaker boom system adopt a fully hydraulic mechanical kinetic control scheme, becoming an efficient alternative to human labor. The maximum crushing force can reach 800 tons, which can easily crush hard ores with a hardness of over 8 on the Mohs scale, equivalent to the workload of dozens of workers working at the same time, thus greatly reducing the dependence on human labor. With the remote control system, the operator does not need to be in the dangerous scene of dust, noise and gravel splash, but can precisely control every action of the rock breaker boom system in the control room through high-definition monitoring and virtual operation interface, bidding farewell to high-intensity and high-risk manual labor.

Applications of BC550 rock breaker boom system

YZH BC550 rock breaker boom system are equipped with YZH's patented rock breaker boom system, which can cover the ports of the rotary and rock crusher in all directions thanks to its multi-axis precision linkage control. Its precise positioning ability allows the crushing head to penetrate into any narrow dead space inside the machine. With the original swing track, the hammer can impact at a high frequency of 120 times per minute in the confined space, which improves the efficiency up to 8 times compared with the traditional manual cleaning method. When a gyratory crusher encounters material bridging or clogging problems, YZH BC550 rock breaker boom system can solve the clogging problem in as little as 15 minutes, dramatically reducing maintenance downtime. After the rock breaker boom system were introduced to a large open pit mine, the average monthly downtime of the gyratory crusher dropped from 48 hours to 6 hours, increasing production capacity by 22% and dramatically enhancing the continuous operation of the production line.

YZH BC550 rock breaker boom systems' modular impactor design provides an advantage in the face of gyratory crushers' common challenges, such as collapsing and vaulting material. It can intelligently adjust the crushing force according to the degree of blockage, which can efficiently release collapsed material while avoiding damage to the lining of the equipment due to excessive impact, thus realizing precise operation. The base of the rock breaker boom system is made of high-strength special steel structure, optimized by finite element design, and when integrated with the gyratory crusher body, it can withstand more than 200 tons of dynamic loads, and is rock-solid even under extreme working conditions.'