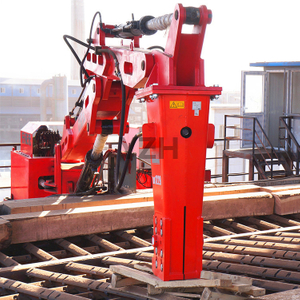

Pedestal Boom Rockbreaker System

In ore crushing, jaw crusher clogging has always been a persistent constraint on production capacity - resulting in downtime accounting for 5% to 20% of the total running time, and directly contributing to 5% to 20% of the production line's capacity loss. Traditional manual blockage clearing is not only inefficient, but also poses a huge safety hazard, and causes unnecessary consumption of labor and power costs. In order to solve this industry pain point, pedestal boom rockbreaker system has become the mainstream choice for global mining companies to optimize production, and YZH brand stands out with its core advantages of high efficiency, high safety factor, easy and reliable operation and low operating costs. According to customer feedback, enterprises that adopt pedestal boom rockbreaker systems have increased productivity by more than 10%, and mines with an annual output value of more than US$3 million can even realize a profit increase of more than US$300,000. Against this background, the BD750 pedestal boom rockbreaker system was born, becoming a new generation of tools to solve the problem of crushing blockage.

Features of pedestal boom rockbreaker system

Diversified control, safe and efficient: Equipped with remote control, cockpit control and 5G remote control system, it can ensure safe and efficient operation in multiple ways, and meet the needs of different operating scenarios.

Excellent performance: It can be adapted with various types of silent hammers, with strong impact power, simple structure and refined technology, and excellent crushing performance.

Flexible installation, strong adaptability: Placement is not restricted, with concrete or steel structure foundation, can be placed on platforms, flat ground, etc., and can be flexibly integrated into different production environments.

Wide range of scenarios and good versatility: It is suitable for use next to grizzly screens, gyratory breakers, silos, etc., and can play a role in many aspects of ore crushing, helping the production process to be smooth.

Advantages of pedestal boom rockbreaker system

Increased productivity: In a crushing line, reduced downtime is critical to overall productivity. pedestal boom rockbreaker systems can quickly and effectively deal with clogs and buildup in the crusher chamber, greatly reducing the downtime caused by clearing clogs and allowing the line to remain in operation for longer periods of time, significantly increasing the tonnage produced per hour, ensuring a constant and stable flow of material, and thus increasing the overall production capacity of the mine.

Safeguard personnel safety: In the traditional way of manually clearing blockages, workers need to be in close contact with the dangerous area and face the risk of being injured by falling materials and mechanical parts. The pedestal boom rockbreaker system supports remote control operation, the operator does not need to be in the dangerous operation site, and can control the equipment in the safe area, which fundamentally reduces the probability of safety accidents, and effectively protects the life safety of employees.

Reduced maintenance costs: the pedestal boom rockbreaker system has reliable performance and stable quality, reducing the number of repairs and maintenance costs due to frequent failures. At the same time, its design is reasonable, the durability of the components is strong, the routine maintenance is relatively simple, do not need to invest too much manpower and material resources for maintenance, thus effectively reducing the mine in the equipment maintenance expenditure.

Control the use of cost: the use of electric motor drive is a major highlight of the pedestal boom rockbreaker system. Compared with the fuel consumption of excavators of the same power, the cost of electricity is only 1/6 of the fuel consumption, which greatly reduces the energy cost during the operation of the pedestal breaker boom system. In the long-term mining production operation, this advantage can save a lot of money for the enterprise, significantly reduce the cost of use and improve economic efficiency.

Convenient and flexible operation: There are various control methods, such as remote control, cockpit control and 5G remote control system, to meet the operational needs in different scenarios and make the operation more convenient and flexible. The operator can choose the most suitable control mode according to the actual situation, realizing efficient and precise operation.

Application of pedestal boom rockbreaker system

Pedestal boom rockbreaker system can deal with clogging problems in large mining crushing plant. The pedestal breaker boom system can intervene remotely to clear clogged feed ports and stuck material in the chamber of core equipment such as jaw crushers and gyratory crushers, ensuring continuous operation of the production line without the need to dismantle and dismantle the machine. At an open pit copper mine in Chile, two 48-inch jaw crushers were used in the crushing plant, which had been down for 1.2 hours a day due to clogging. With the introduction of the pedestal breaker boom system, the response time for clearing the blockage was reduced from 45 minutes to 8 minutes, and the monthly effective operating hours increased by 36 hours. The daily processing capacity of the copper ore was increased by 900 tons, and the annual output value was increased by about 1.8 million US dollars.