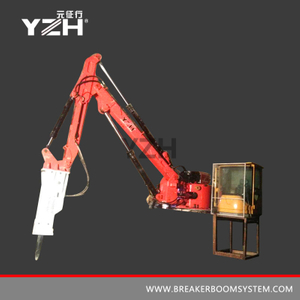

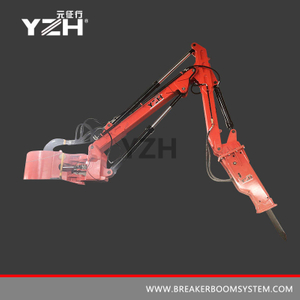

Stationary type pedestal rock breaker boom system

In the production process of mining conveyor lines, due to the lengthy length of the lines, any blockage at the feed or discharge points can easily lead to a complete shutdown of the entire line. Addressing blockage issues not only consumes significant time and effort but also directly results in a decline in investor returns while simultaneously increasing operational costs, causing significant disruptions to production. The WHA560 stationary type pedestal rock breaker boom system is a specialized piece of equipment designed to address such issues. Its operating principle involves an electric motor driving a hydraulic pump, which is then precisely controlled by an hydraulic proportional valve to drive the cylinder in reciprocating motion, thereby efficiently crushing large rocks. In the fields of intelligent control and long-distance communication, the WHA560 stationary type pedestal rock breaker boom system demonstrates exceptional performance. It cleverly combines a remote control with multi-valve control, not only freeing the operator's hands for more convenient operation but also enabling rapid emergency response in unexpected situations, enhancing production safety. The operator-centric cab effectively isolates the operator from harsh external environments, creating a comfortable and pleasant working space that improves operational experience and efficiency. Perhaps most notably, the equipment can be equipped with a 5G remote

control system and intelligent monitoring functionality, truly achieving remote operation and real-time supervision. This feature allows managers to monitor the equipment's operational status without being on-site, enabling timely adjustments to working parameters. This significantly enhances the flexibility and precision of production management, providing robust support for the stable and efficient operation of mining operations.

Parameters of WHA560 Stationary type pedestal rock breaker boom system

| Model No | Unit | WHA560 |

| Boom weight (without hammer) | kg | 2058 |

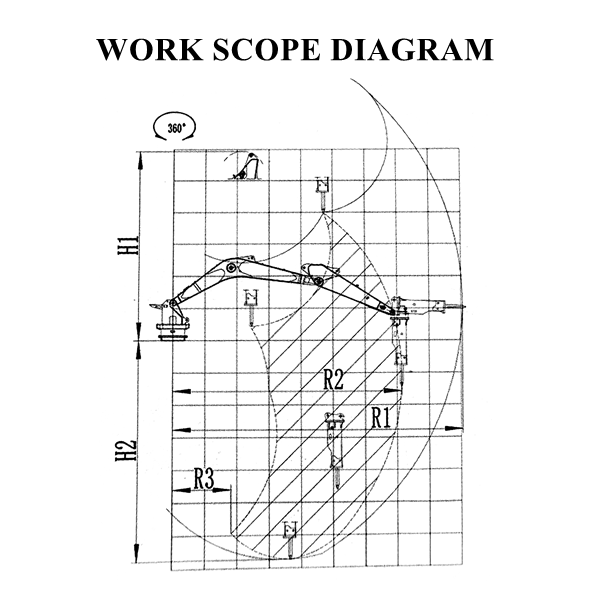

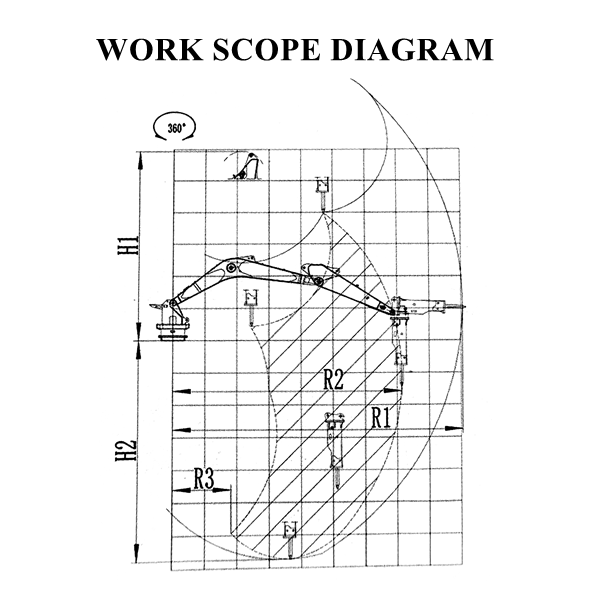

| Max.Horizontal working radius(R1) | mm | 6710 |

| Max.Vertical working radius(R2) | mm | 5150 |

| Min.Vertical working radius(R3) | mm | 1260 |

| Max.Height (H1) | mm | 4400 |

| Max.working depth (H2) | mm | 4820 |

| Rotation | ° | 360 |

| Pedestal Size | mm | 1030×720 |

| Power of Hydraulic Power Unit | kw | 18/22/30

|

Advantages of WHA560 Stationary type pedestal rock breaker boom system

The WHA560 stationary type pedestal rock breaker boom system demonstrates numerous significant advantages in practical applications, bringing tangible benefits to mining production.In terms of extending the service life of subsequent crushers, the secondary crushing function of the WHA560 stationary type pedestal rock breaker boom system is crucial. Minerals extracted from mines often vary in size, with some being large in volume and extremely hard. If these large mineral blocks are directly fed into subsequent crushers, they can cause severe impact and wear on critical components such as jaw plates and liners, leading to premature component failure and a shortened overall service life of the crusher over time. The WHA560 stationary type pedestal rock breaker boom system can perform secondary crushing on these large ore pieces, reducing them to a reasonable particle size that meets the feed requirements of subsequent crushers. As a result, the ore entering the crusher is uniformly sized and has reduced hardness, significantly alleviating the workload on the crusher and reducing component wear. This effectively extends the service life of subsequent crushers and minimises production interruptions and cost increases caused by frequent component replacements or complete crusher replacements.

The WHA560 stationary type pedestal rock breaker boom system's excellent maintenance performance also helps users save a significant amount of operating costs. The WHA560 stationary type pedestal rock breaker boom system is designed with maintenance convenience in mind, featuring a rational layout of key components to facilitate daily inspections, maintenance, and repairs by operators. For example, the core components of the hydraulic system in the WHA560 stationary type pedestal rock breaker boom system adopt a standardized design and are equipped with convenient access panels. In the event of hydraulic system malfunctions, maintenance personnel can quickly disassemble and replace components, thereby reducing repair time. Additionally, the stationary type pedestal rock breaker boom system's wear-prone components are made from high-quality wear-resistant materials, extending component lifespan and reducing replacement frequency. Furthermore, the stationary type pedestal rock breaker boom system is equipped with an intelligent fault diagnosis system that monitors the operational status of all components in real-time, providing timely warnings of potential fault risks. This enables operators to perform preventive maintenance in advance, avoiding large-scale production downtime and high repair costs caused by sudden faults, thereby saving users operational costs from multiple angles.

High safety standards are another key feature of the WHA560 stationary type pedestal rock breaker boom system, ensuring the safety of workers during operations. In terms of design, the WHA560 stationary type pedestal rock breaker boom system is equipped with multiple safety protection devices. For example, the hydraulic system of the WHA560 stationary type pedestal rock breaker boom system features overload protection functionality. When system pressure exceeds the safe range, it automatically relieves pressure to prevent dangerous situations such as hydraulic pipe ruptures caused by overload. In terms of remote control, the 5G remote control system allows operators to perform tasks from a safe cab or control room away from the crushing site, avoiding direct exposure to dust, noise, and vibration in harsh working environments, thereby reducing the risk of occupational diseases. Additionally, the structural strength of the equipment has undergone rigorous testing to withstand the intense impacts and vibrations during crushing operations, ensuring that the equipment does not experience structural failures that could endanger worker safety during operation, thereby comprehensively safeguarding worker safety.

Application of WHA560 Stationary type pedestal rock breaker boom system

In the underground ore chute crushing system, the application of 17 WHA560 stationary type pedestal rock breaker boom systems is a prime example of digital transformation in mining. These WHA560 stationary type pedestal rock breaker boom systems are not simply concentrated in a single area but are scientifically distributed across different working faces and chute openings, functioning like 17 precise and efficient ‘underground guardians’ that each perform their specific tasks while coordinating and collaborating, comprehensively covering the complex crushing operations underground.

Geological conditions and ore characteristics often vary across different work faces. Some areas have harder ore, while others face the challenge of easily clogged chute openings. The WHA560 stationary type pedestal rock breaker boom system, with its strong adaptability, performs reliably at all work sites. For hard ore, it can achieve precise secondary crushing to reduce large ore pieces to an appropriate particle size, preventing chute blockages. At chutes prone to blockages, its efficient crushing capability can promptly clear obstructions, ensuring smooth ore discharge processes. The rational layout of 17 stationary type pedestal rock breaker boom systems has completely transformed the previously dispersed and inefficient underground crushing operations, integrating the entire underground ore discharge chute crushing system into an organic whole and significantly improving operational efficiency.

The surface central control room's centralized remote monitoring and real-time processing mode fully leverages the intelligent advantages of the WHA560 stationary type pedestal rock breaker boom system. In the surface central control room, operators can monitor the real-time operational status of 17 stationary type pedestal rock breaker boom systems underground via high-definition monitoring screens, including crushing progress, equipment parameters, and operational environment information. If any signs of ore blockage appear at a shaft opening, the monitoring system immediately issues an alert. Operators can then remotely control the corresponding stationary type pedestal rock breaker boom system to respond swiftly and perform crushing operations in a timely manner. The entire process does not require personnel to descend into the shaft, thereby saving time and reducing safety risks.

This centralized remote monitoring model also optimizes resource allocation. The central control room can flexibly adjust the working pace of the stationary type pedestal rock breaker boom systems based on the actual conditions of each work area. When the workload in a certain area is heavy, it can coordinate nearby robotic arms to provide support, ensuring the efficient operation of the entire system. At the same time, through the real-time collection and analysis of the operating data of 17 stationary type pedestal rock breaker boom systems, it can also provide accurate data support for mine production planning and equipment maintenance, making management decisions more scientific and reasonable.

As a key component of mine digitization, the application of 17 WHA560 stationary type pedestal rock breaker boom systems has not only driven innovation in underground mining operations but also set a new industry standard. It has broken through the traditional challenges of mining production, such as ‘labour-intensive operations, low efficiency, and numerous safety hazards,’ achieving a leap from ‘underground on-site operations’ to ‘surface-based remote control.’ This has provided a solid technical foundation and practical experience for the digital and intelligent development of mining, while also injecting strong momentum into the industry's transformation and upgrading.