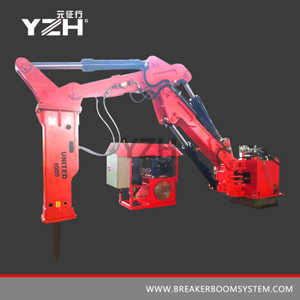

YZH-XL1200R 360° Revolving Stationary Type Pedestal Rock Breaking Booms System

Pedestal Rock Breaker Boom System Applications:

Quarries

Reduce downtime costs of your Crusher. YZH Brand Pedestal Breaker Boom Systems are essential to avoid congestion at the Crusher intake. Keep on working in spite of jams by installing a Pedestal Breaker Booms System that will overcome any eventuality. They are radio‐controlled and have 360° rotation. A complete range with a variety of reaches and features that enable the YZH design a team to tailor them to your crushing plant.

Foundries

Foundries and steel mills are among the most aggressive environments for operation of any machine. The unique design of the Pedestal Rockbreaker Boom System will help you save time in the extraction of all slag and refractory brick. Thanks to their radio control system, Pedestal rockbreaker booms system provide total safety for the operator. They are suitable for areas where access of an excavator is too difficult. A complete range with a variety of reaches and features that enable the YZH design a team to tailor them to your plant.

Tunnelling

YZH Brand Pedestal Rockbreaker Boom Systems are suitable for use in Tunnelling applications where hazardous conditions and confined spaces preclude the use of heavy machinery.

The operator works in complete safety with radio‐controlled, YZH Pedestal Rockbreaker Breaker Booms Systems and enables you to reduce the size of the material before sending it to the crushing process.

Grizzly

Underground mining operations typically use a steel grate called a grizzly to size material before it enters an ore pass. Material that is too large cannot pass through the openings in the grizzly and are left on top of the grizzly to be broken by a pedestal rock breaker booms system, while the smaller material is allowed to pass through the grizzly down the ore pass.

Grizzly applications are extremely harsh by nature. The pedestal boom system is subject to high degrees of in-line and side raking, combined with various sizes and amounts of oversize. YZH’s grizzly stationary pedestal boom systems are designed with wide boom cross sections, extra large pins and reinforced high tensile steel plates. All designed to handle complex loading to the boom.

Gyratory Crusher / Jaw Crusher

Big jobs need big stationary pedestal booms system and hydraulic breakers. YZH’s wide range of gyratory pedestal breaker booms allow full breaker coverage within the rock box and mouth of the Crusher. YZH’s complete line of large hydraulic hammers are designed specifically for gyratories to quickly eliminate any bridging or clogging, restoring consistent material flow to the crusher.

The gyratory crusher is the mainstay of medium to large duty crushing plants. Typically material is brought to the crusher by large haulage trucks and dumped into a rock box. The gyratory crusher is located at the bottom of the rock box. Material is crushed between the eccentrically mounted rotating crushing cone and the fixed, tapered crushing throat.

The stationary rockbreaker booms system is typically mounted in-line with the upper support of the rotating cone called the spider. This provides superior maneuverability of the hydraulic pedestal rockbreaker boom systems within the gyratory throat. The boom is typically sized to allow full range of motion over the working range of the rock box. The reach should be deep enough to allow the breaker to enter the gyratory for material breaking and concave removal applications.

Mobile Crushers

Mobile crushers are, as the name implies, designed to be moved from site to site. An appropriate sized hydraulic fixed rock breaker boom system will mount on the crusher securely so the crusher can be moved without first dismantling the breaker assembly yet be large enough to handle the raking and breaking.

| Unit | YZH-XL1200R |

Weight | Kg | 12500 |

Maximum Reach | m | 14.6 |

Nominal Horizontal Reach (H) | m | 12.2 |

Nominal Vertical Reach (V) | m | 10.4 |

Swing° | ° | 360 |

Base Diameter | m | 1.40 |

Recommended Hydraulic Hammer (Chisel Size) | mm | 140,155,175 |

Recommended Power Packs |

| HA 55, HA 55 HD, HA 75 |