Rockbreaker System

"Professionalism, quality and efficiency", these three words are the most concise evaluation of the rockbreaker system. In the professional level, YZH always customer demand-oriented, in-depth analysis of the characteristics of different working conditions, tailored to provide customers with appropriate equipment to ensure that the scientific and targeted operational programs; in terms of quality, rockbreaker system will be the quality of the core pursuit, with solid craftsmanship and reliable performance, so that the user in the use of the process of no worries, showing the durability of the original color; and high efficiency is YZH's! The factory can efficiently respond to and supply the required products, the after-sales team to quickly solve all kinds of problems, coupled with the rockbreaker systems itself in the mining line operation can greatly enhance the operational efficiency, all-round production speed and efficiency.

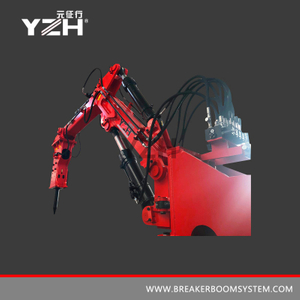

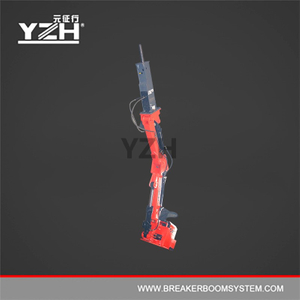

Features of BHC630 rockbreaker system

Full Angle Coverage: With 360° swing angle, it can flexibly adjust the working orientation and cover the crushing area without any dead angle, which can easily cope with the demand of multi-angle crushing under complicated working conditions.

Super Crushing Power: Adopting larger cylinder diameter, the output power is greatly increased, injecting strong power for crushing operation and realizing efficient crushing even with high hardness materials, which significantly improves the working efficiency.

High load-bearing and stable structure: Equipped with thickened axle pins to strengthen the overall rigidity and load-bearing capacity of the rock breaking systems, which can maintain stable operation during long-time and high-intensity operation, effectively reduce structural wear and prolong the service life of the equipment.

Safe and Stable Operation Guarantee: Equipped with a rotary motor with buffer brake, it can accurately buffer the impact force during the rotation process, reduce the vibration and noise during the operation, minimize the mechanical wear and tear, and at the same time ensure the safety and stability of the operation process.

Wide adaptability and efficient vibration: Compatible with YZH1350/YZH1400 models of hammers, with strong adaptability; vibration frequency stabilized at 400-800bpm, high-frequency vibration ensures more thorough crushing effect, and improves the quality and efficiency of operation.

Advantages of BHC630 rockbreaker system

First of all, the remote video remote control system of the BHC630 Rockbreaker Systems allow the operator to operate precisely from the control room. YZH BHC630 Rockbreaker Systems' remote video control is especially advantageous in extreme operating conditions where dust is flying and high temperatures continue to scorch. When the dust concentration exceeds the safety threshold, visibility is less than 3 meters, the thermometer needle always hovering above 40 ℃, the traditional mode of operation, workers need to wear heavy protective equipment in the sweltering environment, not only physical suffering, prolonged exposure may also cause respiratory diseases, heat stroke and other health problems, and obstructed vision is very easy to lead to operational errors. YZH BHC630 Rockbreaker Systems equipped with remote video remote control system, completely breaking this predicament. The BHC630 Rockbreaker Systems are equipped with a high-definition anti-fouling camera, which can still capture clear images even when covered with dust, and with real-time transmission technology, it can accurately project the on-site operation scene onto the display screen in the central control room. The operator only needs to complete a series of actions such as starting and stopping, swinging and crushing of the rock breaking systems through the joystick and touch screen in the cool and clean control room, and the control delay is controlled within 0.5 seconds, which is comparable to the on-site operation in terms of precision.

Secondly, it replaces manual operation and improves safety and efficiency simultaneously. The traditional manual blockage removal method is not only inefficient, but also involves high safety risks - operators need to be in close contact with the crushing area while the equipment is in operation or shutdown, and are vulnerable to the threat of splashing materials, mechanical malfunction, and so on. Rockbreaker systems perform removal tasks through remote control or automated programs, completely freeing manual labor from dangerous environments and radically reducing the probability of safety accidents. At the same time, the stable operating rhythm and high precision of the rockbreaker systems can clear the clogging much faster than manual labor, which further improves the efficiency of dealing with the clogging problem and avoids production delays due to the procrastination of manual operation.

Finally, it is intelligent and highly adaptable, which helps productivity to jump up. Modern Rockbreaker systems integrate advanced control system and supports various control methods (such as remote console, intelligent programming, etc.), which is convenient to operate and can be adapted to different mining operation scenarios. Its flexible operating range and strong environmental adaptability enable it to operate stably in complex mining environments such as dusty and narrow spaces. Taking the rockbreaker system as an example, its intelligent cooperative operation mode can be efficiently linked with other equipment in the crushing line, and according to feedback from domestic and foreign customers, the productivity of mines equipped with this system has increased by more than 10%. For a mine with an annual output of US$3 million, this means an additional revenue of more than US$300,000 per year, which fully demonstrates the significant role of Rock breaking systems in improving production efficiency.

Application of BHC630 rockbreaker system

Rockbreaker systems can accurately respond to the clogging situation that occurs from time to time at the feed opening, and through its powerful crushing capacity, it can carry out secondary crushing of oversized ores, so as to cut off the source of clogging and avoid interruption of the production line due to clogging. Rock breaking systems design has been carefully polished to flexibly meet the needs of a wide range of crushing operations, whether it is the compact layout of a small gravel quarry, or the open operating area of a large mine, it can be easily adapted to a wide range of application scenarios.

The most impressive advantage of this machine is its ability to handle the jammed material at the inlet of two crushers at the same time. This means that in the past, two sets of equipment need to work separately in the scene, now rockbreaker systems can be efficiently completed, significantly reducing the cost of equipment investment, but also significantly improve the overall operating efficiency. The operation mode is also humanized, the operator can operate the equipment in the comfortable cab through the precise control system, but also with the help of wireless remote control to realize remote control, especially in some complex environment, there are security risks in the area, remote operation can maximize the protection of personnel safety, and flexibly cope with the operational needs of different operating environments. When large stones appear in the feed opening of the crusher, threatening the normal feeding, this rockbreaker systems can respond quickly, crushing and unblocking the large stones in a timely manner with efficient crushing strength and precise operation.

The whole process requires no downtime, allowing the entire production line of the sand and gravel aggregate yard to keep running smoothly at all times. It not only has high operating efficiency and can solve the blockage problem in a short time, but also has strong safety, with multiple guarantees from equipment operation to personnel operation. This undoubtedly wins the time of continuous production for the enterprise, avoids the loss caused by downtime, and provides a solid and reliable guarantee for obtaining higher profits.