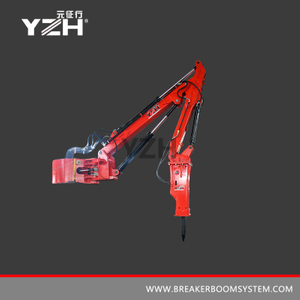

Rockbreaker boom system

In the harsh scenarios of material production and rock fragmentation, efficiency, safety, and stability are eternal pursuits. YZH BHB350 rockbreaker boom system focuses on the difficult operation of the crushing port, covering the fixed jaw crusher port, the feed port of the rotary crusher, and the mobile crushing station in depth.In the handling of materials in hazardous environments, it is a reliable "attacker" who lays a solid foundation for the smooth operation of the crushing process. Whether it is the handling of hard coal blocks or the critical process of rock crushing, YZH rockbreaker boom system can accurately exert force to solve problems such as material accumulation and blockage, ensuring production continuity.

BHB350 rockbreaker boom system has a sturdy steel structure "skeleton" made of high-strength steel, with a maximum load capacity of up to 5000 kilograms. It has excellent durability and can serve stably for a long time under high-intensity working conditions such as intensive material operation and demolition operations, resisting impact and wear during crushing operations, becoming a reliable production "partner".The advanced hydraulic system is its power "heart", accurately controlling the movement of the rockbreaker boom system to achieve efficient and stable material grasping, crushing assistance and other operations, making every operation powerful and precise.

The accompanying cockpit is a "comfortable fortress" designed for operators. Standard configuration ergonomic chair, conforms to the curve of the human body, reduces long-term work fatigue; Hydraulic joystick control, precise and convenient operation, reduces labor intensity.More flexible options for air conditioning and heaters can be added, creating a suitable temperature environment regardless of hot or cold weather, allowing operators to focus on their work and improve work efficiency and safety.

Parameters of BHB350 stationary type rockbreaker boom system

| Model No | Unit | BHB350 |

| Boom weight (without hammer) | kg | 3030 |

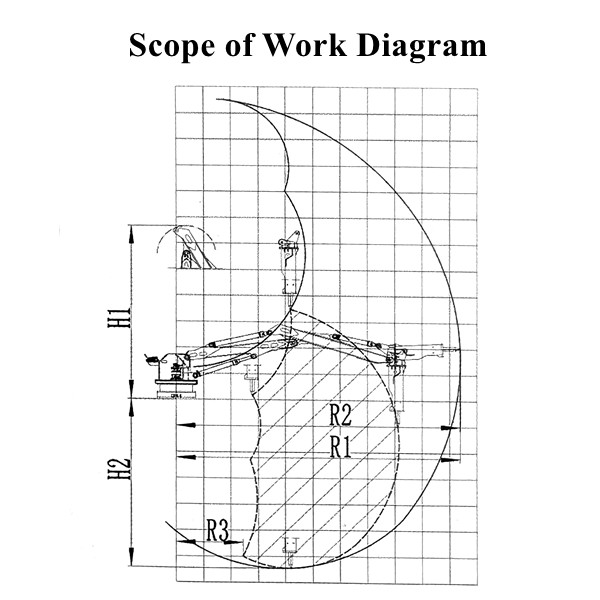

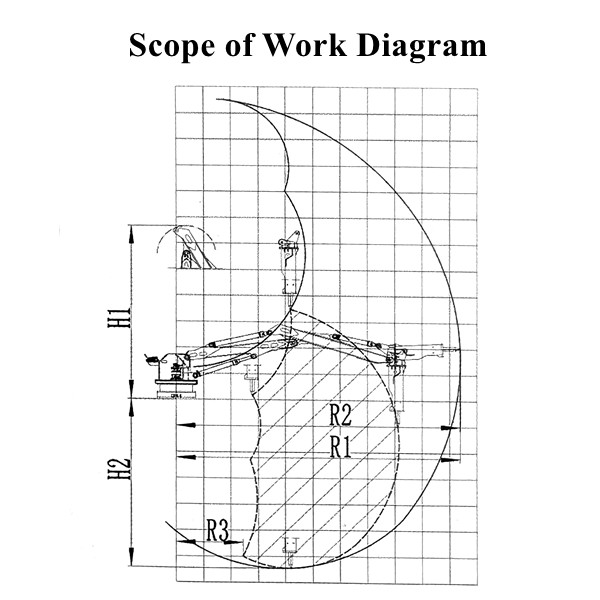

| Max.Horizontal working radius(R1) | mm | 5890 |

| Max.Vertical working radius(R2) | mm | 3830 |

| Min.Vertical working radius(R3) | mm | 1790 |

| Max.Height (H1) | mm | 3580 |

| Max.working depth (H2) | mm | 3750 |

| Rotation | ° | 360 |

| Pedestal Size | mm | Φ800 |

| Power of Hydraulic Power Unit | kw | 37/45/55

|

Features of BHB350 rockbreaker boom system

Deploy flexibility. BHB350 rockbreaker boom system breaks space limitations and can be placed on support frames constructed with steel structures, flexibly adapting to different factory layouts and production line requirements.For materials such as coal blocks transported by the production line, it can accurately align and process them without the need for large-scale production site renovation, reducing deployment costs for enterprises, improving production line adaptability, and making crushing operations more smoothly integrated into the production process.

Wide range of motion is available. 360° continuous rotation capability, combined with an extension distance of up to 5890mm, creates a wide workspace.Whether it's cleaning materials in narrow crushing chambers or assisting with large-scale material handling, it can be flexibly covered, just like installing a "flexible arm" on a crusher, breaking through the spatial constraints of traditional operations and making complex crushing operations easy to complete.

Double upgrade of safety and efficiency.In the field of material production and rock crushing, time and safety are of paramount importance. YZH BHB350 rockbreaker boom system provides a safer mode for blockage management and removal of debris in the crushing chamber by constructing a crusher boom system. By adding static pedestal boom system to the primary crushing station, workers do not need to be exposed to hazardous crushing environments, and can remotely and accurately operate the rockbreaker boom system to complete cleaning, greatly reducing safety risks and safeguarding team safety.

Advantages of BHB350 rockbreaker boom system

BHB350 rockbreaker boom system effectively reduces factory downtime.Traditional manual cleaning of blockages and accumulations is time-consuming and labor-intensive, while BHB350 static pedestal rockbreaker boom system responds quickly and operates efficiently, ensuring continuous material flow and increasing hourly production tonnage, making the production pace compact and orderly.The static pedestal rockbreaker boom system developed by YZH is designed for maximum productivity and optimal cost-effectiveness in factories. From equipment procurement to long-term operation, static pedestal boom system helps enterprises control production costs, improve production efficiency, and gain advantages in fierce market competition through stable and efficient production.

BHB350 static pedestal boom system redefines the crushing operation mode with innovative design and excellent performance.From adapting to diverse scenarios, to robust and intelligent construction, flexible and efficient operation, to the dual value creation of safety and efficiency, it is a powerful assistant in the fields of material production and rock crushing.

In the future, with the continuous improvement of production requirements in the industry, BHB350 static pedestal rockbreaker boom system is expected to continue iterating, solving the problem of crushing operations for more enterprises, promoting crushing production towards safer, more efficient, and intelligent development, becoming a key force in reshaping the crushing operation ecology, helping enterprises steadily move forward on the production track, and harvest more value.