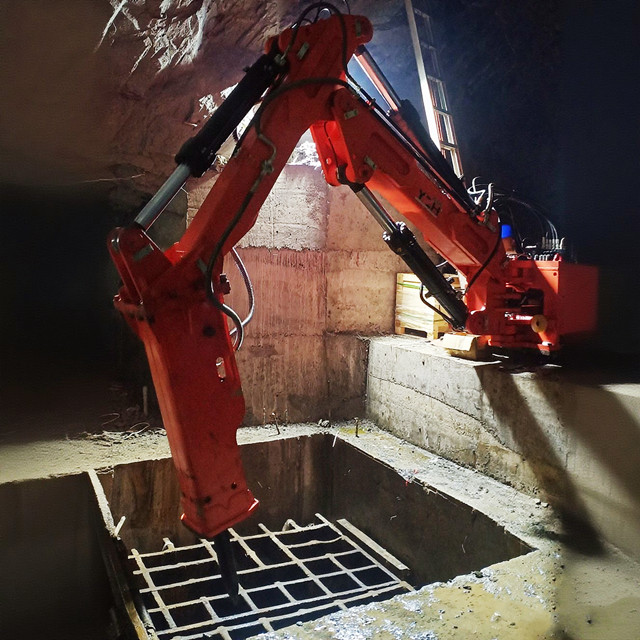

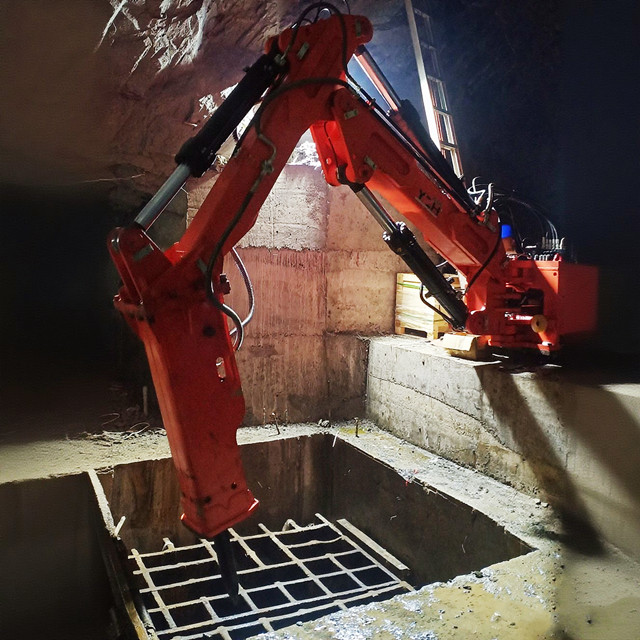

Hydraulic rock breaker boom system

Conducting rock crushing operations in underground mines often presents significant challenges due to the confined space. The introduction of the BA400 hydraulic rock breaker boom system provides an ideal solution to this problem. The BA400 hydraulic rock breaker boom system boasts exceptional spatial adaptability, with a maximum working radius of just 1,513 millimeters, enabling it to operate flexibly within the confined spaces of underground mines. Its maximum height is also only 3,440 millimeters, and its compact design allows it to rotate freely underground without obstruction. The hydraulic station paired with it also balances size and performance. Its dimensions are 1,580 millimeters × 756 millimeters × 1,250 millimeters, making it perfectly compatible with the BA400 hydraulic rock breaker boom system in underground mines without occupying excessive space. Notably, the hydraulic station does not compromise power despite its compact size, typically equipped with a 30 kW motor to provide robust and stable power support for efficient crushing operations.

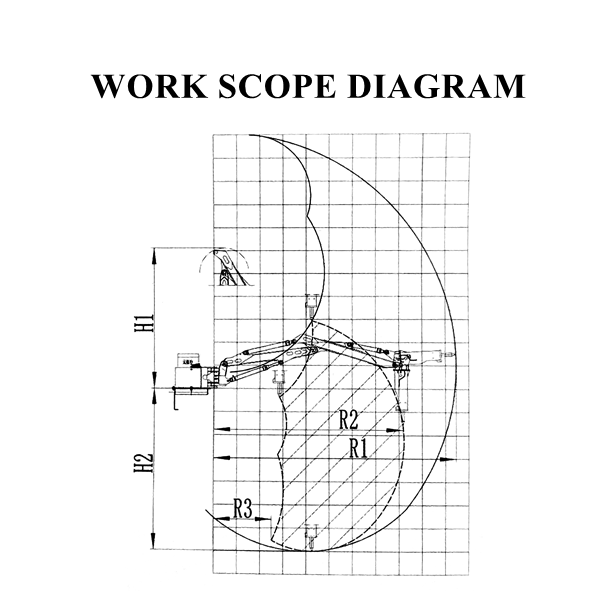

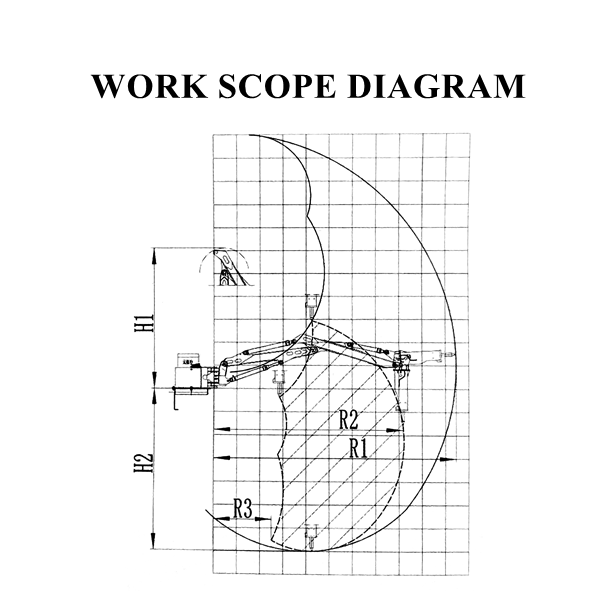

Parameters of BA400 stationary type pedestal rockbreaker system

| Model No | Unit | BA400 |

| Boom weight (without hammer) | kg | 1513 |

| Max.Horizontal working radius(R1) | mm | 5820 |

| Max.Vertical working radius(R2) | mm | 4210 |

| Min.Vertical working radius(R3) | mm | 1885 |

| Max.Height (H1) | mm | 3440 |

| Max.working depth (H2) | mm | 3650 |

| Rotation | ° | 170 |

| Pedestal Size | mm | 1030×720 |

| Power of Hydraulic Power Unit | kw | 18/22/30

|

Characteristics of BA400 hydraulic rock breaker boom system

The BA400 hydraulic rock breaker boom system is particularly notable for its maneuverability and flexibility, enabling it to respond quickly to various complex working conditions. Hydraulic rock breaker boom system can extend and retract freely in narrow spaces or emergency blockage scenarios, efficiently completing processing tasks and significantly reducing preparation time, providing a powerful guarantee for rapid problem resolution.

In terms of crushing capacity, the BA400 hydraulic rock breaker boom system is exceptionally powerful. It can be flexibly paired with various models of crushing hammers, offering exceptional adaptability, allowing users to select the appropriate tool based on different crushing requirements. Its maximum impact energy reaches 2,035 joules, enabling it to effortlessly crush mudstone and sandstone with strengths ranging from 1,050 to 200 MPa. Whether dealing with hard rock layers or highly viscous mudstone formations, hydraulic rock breaker boom system can efficiently process them, significantly enhancing crushing operation efficiency.

In terms of detail, the BA400 hydraulic rock breaker boom system demonstrates a rigorous approach to craftsmanship. Every oil pipe in the hydraulic rock breaker boom system has been carefully processed to ensure correct and tight connections, effectively avoiding faults such as oil leaks and insufficient pressure caused by oil pipe connection problems. At the same time, oil pipe protection sleeves are provided at necessary locations to provide additional protection for the oil pipes, reducing damage caused by external friction and collisions, significantly extending the service life of the oil pipes, and reducing equipment maintenance costs and failure rates.

Notably, the BA400 hydraulic rock breaker boom system features remote operation capabilities, a feature that significantly enhances operational safety and convenience. Operators can precisely control the equipment's operation from a safe distance using the remote control system, thereby avoiding direct exposure to the dust, noise, and potential flying debris hazards associated with crushing operations. This also allows for more flexible adaptation to complex operational environments, ensuring stable equipment operation and precise performance even in areas with poor visibility or where personnel cannot easily access.

Application of BA400 hydraulic rock breaker boom system

In the complex operating environment of underground metal mines, the BA400 hydraulic rock breaker boom system, with its targeted design, has become a key piece of equipment for improving production efficiency. The tunnels, ore passageways, and dumping points in underground metal mines are often narrow spaces where large equipment is difficult to maneuver due to its bulky size. The BA400 hydraulic rock breaker boom system compact design is perfectly suited for such restricted environments — its optimized dimensions allow it to be easily positioned in narrow passages, fundamentally resolving the challenges of large equipment being unable to enter or maneuver effectively.

More importantly, the BA400 hydraulic rock breaker boom system rotation angle and extension height have been precisely calibrated. At the opening of the ore channel, it can adjust its working angle through flexible rotation to precisely target the area to be processed. When faced with vertical spaces with limited clearance, such as dumping points, its reasonable extension height can cover blockage points at different heights, enabling crushing operations in both upper and lower areas without frequent repositioning of the machine. This feature significantly enhances efficiency when addressing blockages in space-constrained areas, eliminating the need for repeated repositioning caused by insufficient operational range in traditional equipment, thereby drastically reducing idle operation time.

In actual production, underground mines often experience blockages in passages or dumping points due to oversized ore blocks, resulting in interruptions in material flow. The BA400 hydraulic rock breaker boom system can directly penetrate the core of the blockage and utilize its powerful crushing capability to break down oversized materials into smaller pieces that meet conveying standards, quickly restoring material flow. This “point-to-point” precise handling not only shortens the blockage resolution cycle but also reduces production downtime caused by material buildup, indirectly enhancing the overall productivity of the mine. For underground metal mines that require continuous assurance of smooth material flow, the BA400 hydraulic rock breaker boom system serves as both an “obstacle-clearing expert” for addressing emergency blockages and an “efficient assistant” for maintaining production rhythm.