Stationary type fixed rockbreaker system

The WHA610 stationary type fixed rockbreaker system exhibits significant advantages in performance parameters.The stationary type fixed rockbreaker system without a hammer weighs approximately 2196KG, and its lightweight design provides a solid foundation for operational flexibility.In terms of homework scope, compared to the maximum working radius of 6000mm of WHA460 model, the working radius of WHA610 stationary type fixed rockbreaker system has been significantly extended by 1530mm. This significant improvement means that it can cover a wider work area, effectively reduce the number of equipment movements, and improve overall work efficiency, especially highlighting its advantages in large-scale site crushing operations.It is worth mentioning that the Stationary type fixed rockbreaker system is completely powered by an electric motor.This design has brought breakthrough performance in energy consumption. Compared with hydraulic excavators powered by engines, it reduces energy consumption costs by more than 85% under the same crushing power. Long term use can save users a lot of operating costs, and it is also more energy-efficient and environmentally friendly, in line with the green development concept of modern industrial production.

Parameters of WHA610 Stationary type fixed rockbreaker boom system

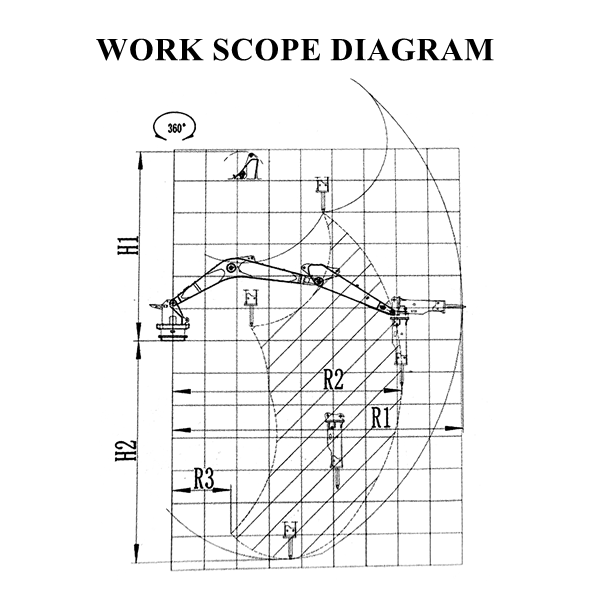

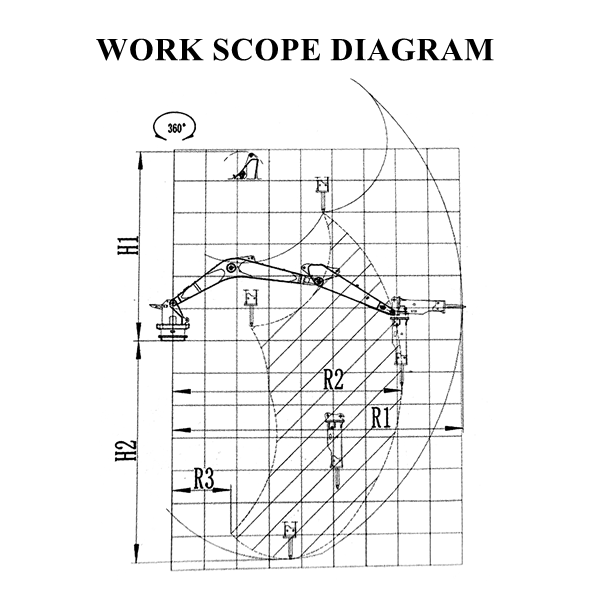

| Model No | Unit | WHA610 |

| Boom weight (without hammer) | kg | 2196 |

| Max.Horizontal working radius(R1) | mm | 7530 |

| Max.Vertical working radius(R2) | mm | 6090 |

| Min.Vertical working radius(R3) | mm | 1680 |

| Max.Height (H1) | mm | 4262 |

| Max.working depth (H2) | mm | 5785 |

| Rotation | ° | 360 |

| Pedestal Size | mm | 1030×720 |

| Power of Hydraulic Power Unit | kw | 18/22/30 |

Characteristic of WHA610 Stationary type fixed rockbreaker system

One of its core advantages is the ultra heavy boom, which, coupled with a hammer free working arm weight of approximately 2196KG, not only endows the structure with super strong stability and load-bearing capacity, but also provides reliable support for efficient operations. Even in the face of high-intensity crushing tasks, Stationary type fixed rockbreaker system can handle them calmly.

In terms of homework coverage, it has achieved significant breakthroughs.Compared to the maximum working radius of 6000mm of the WHA460 model, the working radius of the WHA610 Stationary type fixed rockbreaker system extends by 1530mm. This leap allows it to easily reach a wider working area, significantly reducing equipment displacement frequency and significantly improving the overall efficiency of large-scale site crushing operations.

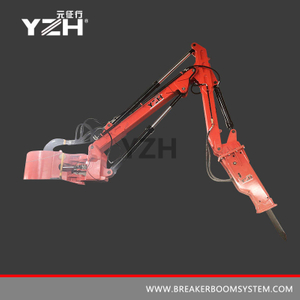

The modular design highlights its flexible adaptability, which can perfectly accommodate various types of hammers such as YZH680, YZH750, YZH800, YZH850, etc. It can quickly switch according to the needs of different crushing scenarios, greatly enhancing the versatility of the equipment and allowing one stationary type fixed rockbreaker system to handle multiple job tasks.

Application of WHA610 Stationary type fixed rockbreaker system

In work scenarios with strict space requirements, the WHA610 Stationary type fixed rockbreaker system has become an ideal choice for efficient operations due to its ultimate installation space optimization.

Compared to the traditional fixed hydraulic crushing working arm that usually requires a larger space foundation, WHA610 Stationary type fixed rockbreaker system has achieved a breakthrough upgrade in design. The fixed installation foundation can be compressed to a minimum of 2 meters by 2 meters, requiring only 50% of the conventional installation space, greatly reducing the need for site occupation.

More flexibly, the height of the installation foundation can be flexibly designed according to the on-site working conditions (such as operating height, material stacking situation, etc.) - for example, in practical applications, WHA610 Stationary type fixed rockbreaker system can be directly deployed on a 1 meter by 2 meter high platform, which not only avoids ground layout restrictions by using vertical space, but also improves the coverage range of operations through the height of the high platform, achieving the dual advantages of "small space+high efficiency".

This compact design is not only suitable for crushing operations in narrow workshops and warehouses, but also for rapid deployment in outdoor restricted areas (such as building ruins and mine tunnels), reducing the cost of early site renovation while ensuring the strong power and operational accuracy of hydraulic crushing, perfectly balancing space economy and crushing efficiency.