Pedestal type boom rock breaker system

In modern industrial production, the material crushing process is crucial.The BAN310 Pedestal type boom rock breaker system has become an ideal choice for many industries due to its comprehensive certification standards, excellent structural design, intelligent control system, and high-performance crushing capability.

BAN310 Pedestal type boom rock breaker system has an impressive certification qualification and holds a CE certificate, which means it complies with European safety, health, and environmental standards.At the same time, the certification of ISO9001 quality management system, ISO14001 environmental management system, and ISO45001 occupational health and safety management system demonstrates its outstanding performance in quality, environmental protection, and safety.

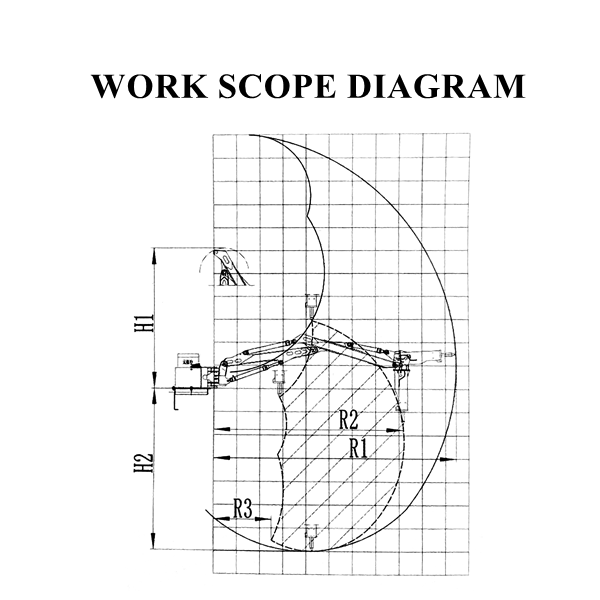

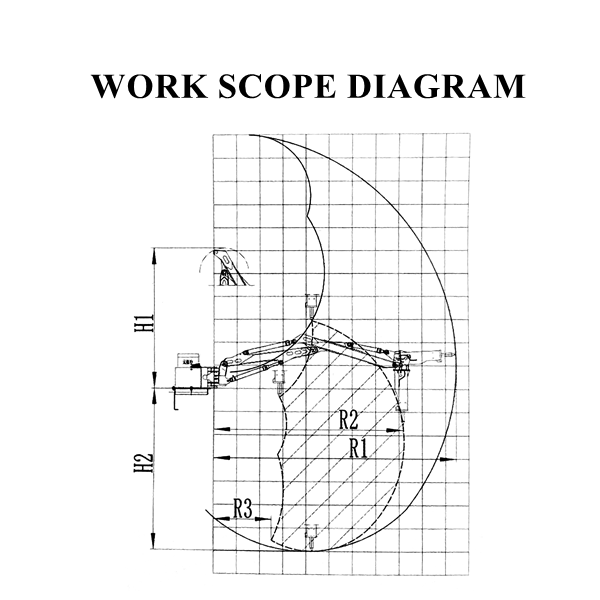

From the perspective of structural parameters, the weight of BAN310 working arm (without hammer) is 1411kg, demonstrating a solid and stable foundation.Its maximum horizontal working radius is 5300mm, maximum vertical working radius is 3690mm, minimum vertical working radius is 1800mm, and maximum height is 2530mm. This size design allows it to flexibly operate in different work scenarios, accurately cover the work area, and efficiently complete crushing tasks.

Parameters of WHA610 Stationary type fixed rockbreaker boom system

| Model No | Unit | BAN310 |

| Boom weight (without hammer) | kg | 1411 |

| Max.Horizontal working radius(R1) | mm | 5300 |

| Max.Vertical working radius(R2) | mm | 3690 |

| Min.Vertical working radius(R3) | mm | 1800 |

| Max.Height (H1) | mm | 2530 |

| Max.working depth (H2) | mm | 3830 |

| Rotation | ° | 170 |

| Pedestal Size | mm | 1030×720 |

| Power of Hydraulic Power Unit | kw | 18/22/30 |

The intelligent control system is a major highlight of BAN310 Pedestal type boom rock breaker system.Supporting remote control over distances of 10-20km and equipped with a video surveillance system, operators can work in safe areas far from danger, greatly ensuring personnel safety.Flexible control technology enables the fixed-point positioning and striking of the breaking hammer with extremely high accuracy, effectively reducing ineffective impacts and improving work efficiency.Multi parameter fusion control with integrated high-performance controller, capable of real-time adjustment of crushing force and frequency, can easily cope with materials of any hardness, and intelligently adapt.

In terms of high-efficiency crushing capacity, BAN310 pedestal type boom rock breaker system adopts a 18-30kW hydraulic station (BAN310 standard power 18/22/30kW), which strongly drives high-performance crushing hammers with impact energy far exceeding traditional equipment, easily crushing various hard materials.Its system integration is high, with a failure rate reduced by 85% compared to diesel equipment, and it can operate stably year-round, providing strong support for the continuous production of enterprises.

The BAN310 pedestal type boom rock breaker system, with its rigorous certification standards, scientific structural design, advanced intelligent control, and efficient crushing capabilities, has demonstrated its prowess in fields such as mines, quarries, sand and gravel aggregate production lines, and metallurgical foundries. Pedestal type boom rock breaker system brings safer, more efficient, and intelligent solutions to industrial crushing operations and is a powerful assistant in promoting industry development.