Pedestal Rockbreaker System

WHB710 is one of a very popular model in China! WHB710 Pedestal Rockbreaker System deeply integrates modern crushing equipment with traditional sand production process, and through technological innovations such as intelligent control, long-distance communication, and environment sensing, YZH Pedestal Rockbreaker System creates a heavy-duty construction machinery equipment that combines safety, efficiency, and flexibility. Whether it is a fixed jaw crusher opening, gyratory crusher inlet, or mobile crushing plant, WHB710 pedestal rockbreaker system can accurately cope with the processing needs of oversized materials, becoming an indispensable "blockage-breaking expert" in mining operations.

Parameters of WHB710 stationary type pedestal rockbreaker system

| Model No | Unit | WHB710 |

| Boom weight (without hammer) | kg | 3248 |

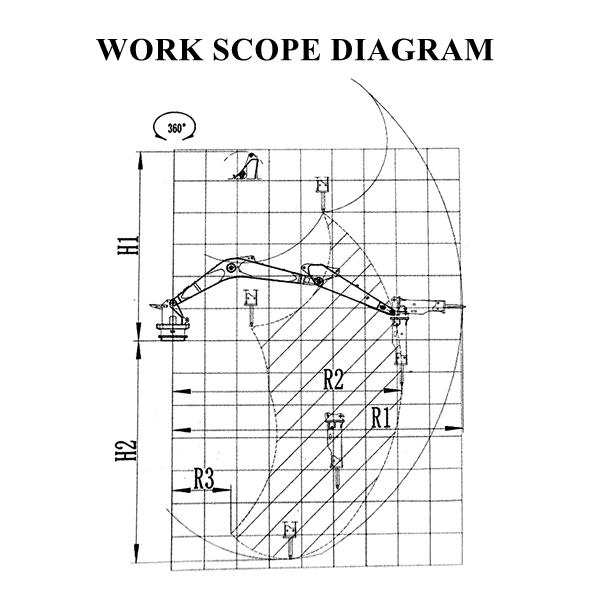

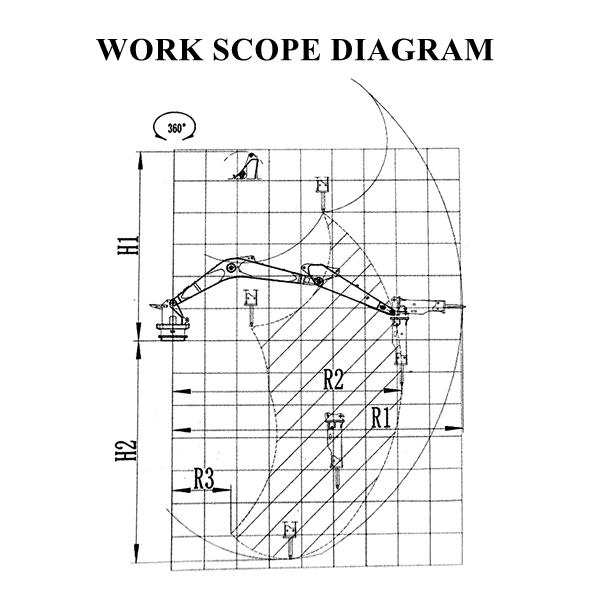

| Max.Horizontal working radius(R1) | mm | 9000 |

| Max.Vertical working radius(R2) | mm | 7150 |

| Min.Vertical working radius(R3) | mm | 2440 |

| Max.Height (H1) | mm | 6000 |

| Max.working depth (H2) | mm | 6740 |

| Rotation | ° | 360 |

| Pedestal Size | mm | Φ900 |

| Power of Hydraulic Power Unit | kw | 37/45/55 |

Features of WHB710 pedestal rockbreaker system

The core competitiveness of WHB710 Pedestal Rockbreaker System from its hard-core technical configuration and humanized design details, which embodies the design concept of "Heavy-duty and Durable, Flexible and High-efficiency" from the structure to the function, and the specific features are as follows:

The base boom has excellent performance: it adopts heavy-duty, durable and high-strength steel structure, and the maximum payload can reach 9000 kilograms, which can easily cope with heavy material handling and crushing operations. The lubrication system can be selected flexibly, either with Lincoln brand centralized automatic lubrication system to realize unmanned maintenance and reduce human intervention, or with centralized manual lubrication system to meet the maintenance needs of different scenarios, and support customized configuration to adapt to diversified operating environments.

Powerful and reliable power and hydraulics: A powerful drive unit consisting of a 55 kW motor and a hydraulic pump with a hydraulic flow rate of up to 110 liters per minute provides sufficient power for flexible operation of the pedestal rockbreaker system and crushing work. For special environmental requirements, the Arctic package can be equipped to ensure stable operation at temperatures as low as -40°C, breaking through the climate limitations. The hydraulic system adopts quick coupling design, which supports the quick replacement of attachments and the rapid switching of different working parts such as crushing hammer and grapple, which greatly enhances the versatility and adaptability of the Pedestal Rockbreaker System.

Easy to operate and highly flexible: Equipped with an easy-to-operate control handle, the operating logic is simple and intuitive, allowing even novices to get started quickly and reducing personnel training costs. The Pedestal Rockbreaker System can rotate 360° and has a maximum working radius of 9,000 millimeters, covering a wider working area, and can be flexibly adjusted to handle blockages or oversized materials in confined spaces or under complex working conditions.

Diversified Applications of WHB710 pedestal rockbreaker system

WHB710 pedestal rockbreaker system has a wide range of application scenarios, covering almost all areas of heavy industry where heavy materials need to be handled, and its core value lies in replacing manual labor through mechanized operation to achieve the double enhancement of safety and efficiency.

The pedestal rockbreaker system is used in quarries and open pit mines to remove oversized boulders from crusher inlets and discharge points in loading areas. In traditional operations, manual handling of such boulders is not only time-consuming and laborious, but also faces a high risk of being injured by falling rocks. The pedestal rockbreaker system can accurately move boulders to the designated area or crush them directly through remote control, which not only ensures operational safety, but also quickly clears the blockage points, ensures the continuity of material transportation, and significantly improves the overall production efficiency of the quarry.

In underground metal mines, due to the narrow space of ore access openings and dumping points, it is difficult for large equipment to enter, and manual handling of oversized materials is extremely inefficient and poses safety risks.With its compact structural design and flexible boom operation, the pedestal rockbreaker system can work freely in the limited space, efficiently handle and crush oversized ores, effectively improve the efficiency of underground material flow, and reduce the downtime due to clogged materials. The compact design and flexible jib operating capability of the pedestal rockbreaker system allows it to operate in limited space, efficiently handling and crushing oversized ores.

In addition, the pedestal rockbreaker system also plays an important role in heavy industries such as demolition, construction and recycling. When confronted with heavy and bulky construction or recycling materials, as well as large objects that are difficult to handle manually, the pedestal rockbreaker system can break them down through its powerful hydraulic crushing function, and then combine it with its flexible handling capability to realize centralized material handling. Whether it's a dangerous demolition site or an inefficient manual handling scenario, the pedestal rockbreaker system can optimize the process through mechanized operation, reduce manual labor intensity, and avoid safety accidents at the same time.

WHB710 pedestal rockbreaker system has become the core equipment for solving the problem of material clogging and improving operational efficiency in heavy ind ustry by virtue of its high-strength structure, powerful power system, flexible operational performance and wide adaptability to various scenarios. It not only redefines the material handling mode of mining and heavy industry, but also provides solid technical support for enterprises to realize safe, intelligent and efficient production.